SSR1300 Power Supply Maintenance

Maintaining an SSR1300 appliance includes replacing power supplies. Replacing includes removing a failed power supply and installing a functional power supply.

Replacing an AC Power Supply on the SSR1300

The two AC power supplies (part number: JNP-650W-AC-SSRHE) are hot-removable and hot-insertable field-replaceable units (FRUs) installed in the rear panel of the SSR1300 appliance. You can remove and replace them without powering off the SSR1300 or disrupting the SSR1300 functions.

Ensure that you have the following parts and tools available:

-

ESD grounding strap

-

Antistatic bag or an antistatic mat

-

Replacement AC power supply

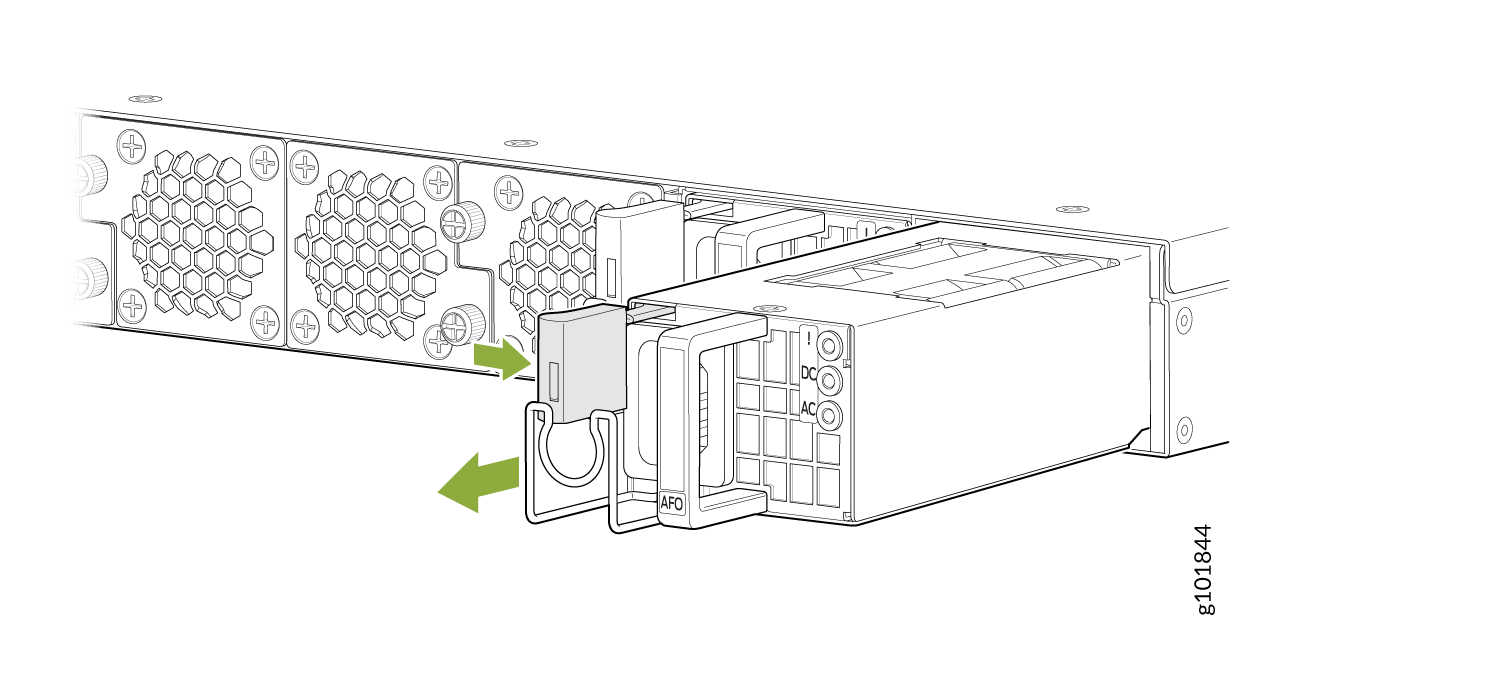

Removing the AC Power Supply from an SSR1300

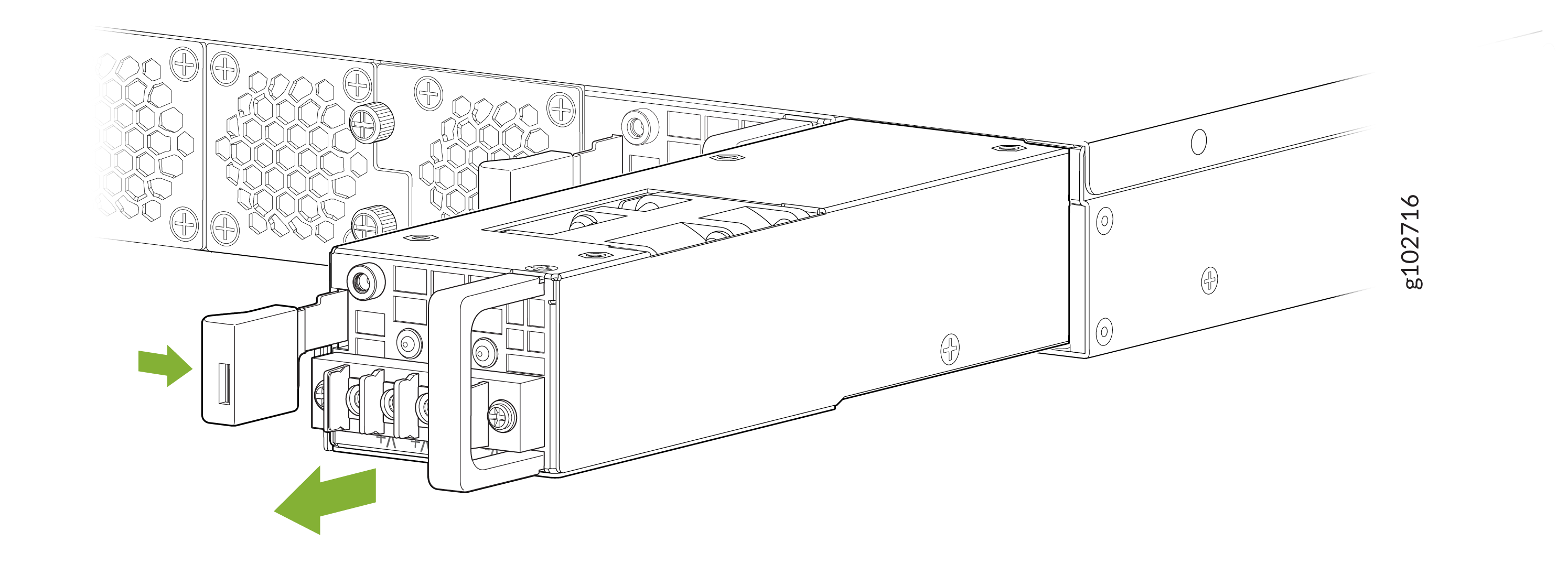

To remove a power supply from the appliance (see Figure 1):

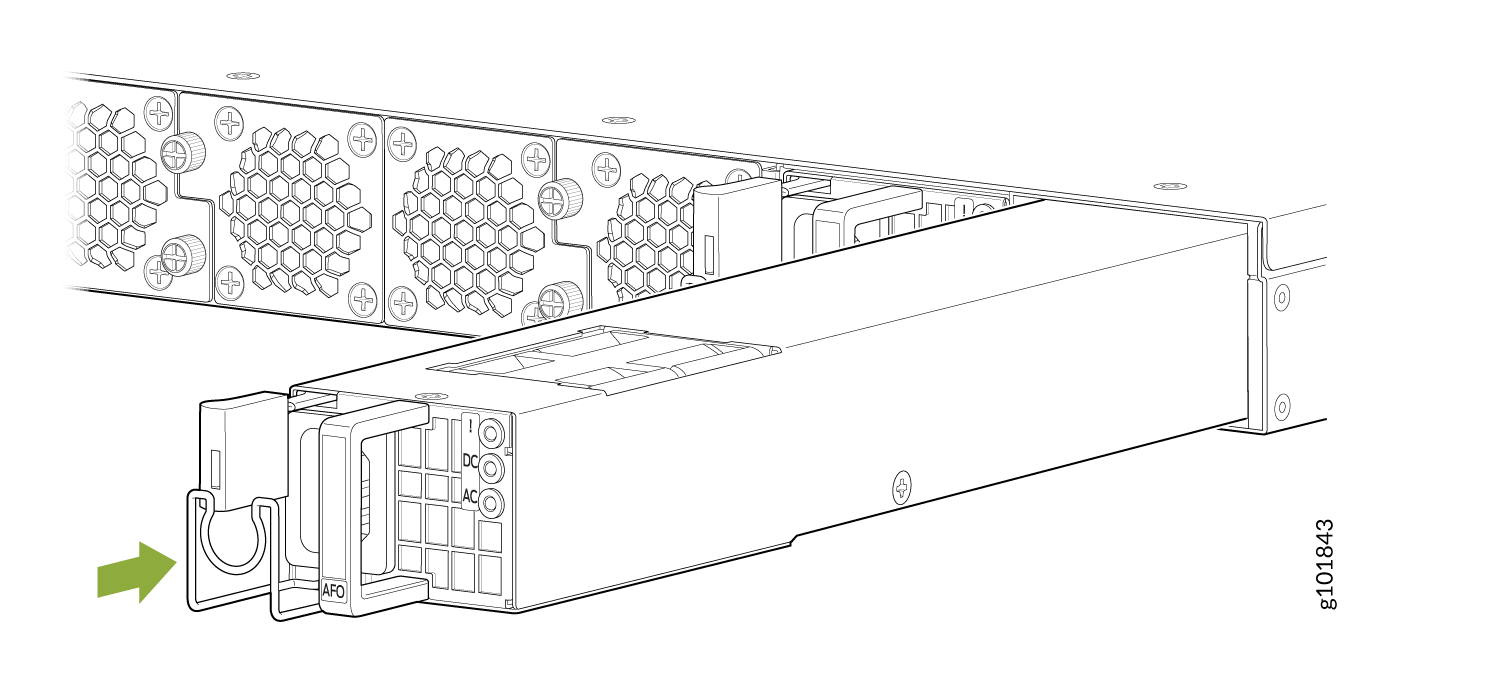

Installing the AC Power Supply in an SSR1300

To install an AC power supply (see Figure 2):

Replacing a DC Power Supply on the SSR1300-DC

The two DC power supplies (part number: JPSU-650W-DC-F-AFO) are field-replaceable units (FRUs) installed in the rear panel of the SSR1300-DC appliance. However, due to the DC power requirements the entire unit must be taken off line and powered down.

Do not attempt to install a DC power supply into an SSR1300 that originally contained an AC power supply. This may result in damage to the SSR1300, and the appliance may not function.

In most cases, electrical code requires that DC connection be performed by a licensed professional. Please consult your local electrical codes before replacing a DC power supply.

Ensure that you have the following parts and tools available:

-

ESD grounding strap

-

Antistatic bag or an antistatic mat

-

Replacement DC power supply

-

#2 Phillips Screwdriver

There are three tasks to replace the DC power supply:

-

Disconnect Power

-

Remove the existing DC power supply

-

Install the new DC power supply

Removing a DC Power Supply from the SSR1300-DC

Up to two power supplies can be located at the rear of the chassis on the right side. Each DC power supply weighs approximately 2.20 lbs (1 kg).

Do not leave a power supply slot empty for more than 30 minutes while the SSR is operational. For proper airflow, the power supply must remain in the chassis, or a blank panel must be used in the empty slot.

After powering off a power supply, wait at least 60 seconds before turning it back on.

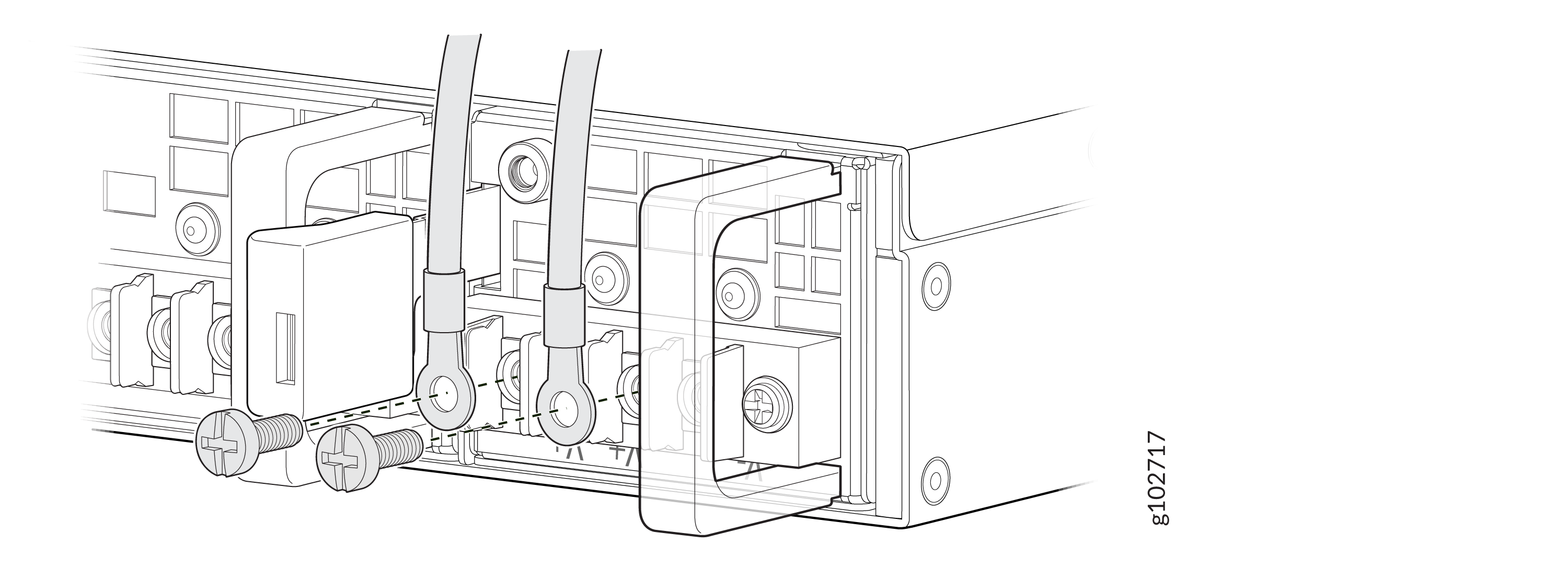

Wire the DC power supply using the appropriate lugs. When disconnecting power, the proper wiring sequence is:

Negative (–) DC source power cable lug to a -48V (input) terminal

Positive (+) DC source power cable lug to a (+) RTN (return) terminal.

Ground to Ground

Note that the ground wire should always be connected first and disconnected last.

To remove a DC power supply:

Installing a DC Power Supply in the SSR1300-DC

Wire the DC power supply using the appropriate lugs. When connecting power, the proper wiring sequence is:

Ground to Ground

Positive (+) DC source power cable lug to a (+) RTN (return) terminal.

Negative (–) DC source power cable lug to a -48V (input) terminal

Note that the ground wire should always be connected first and disconnected last.

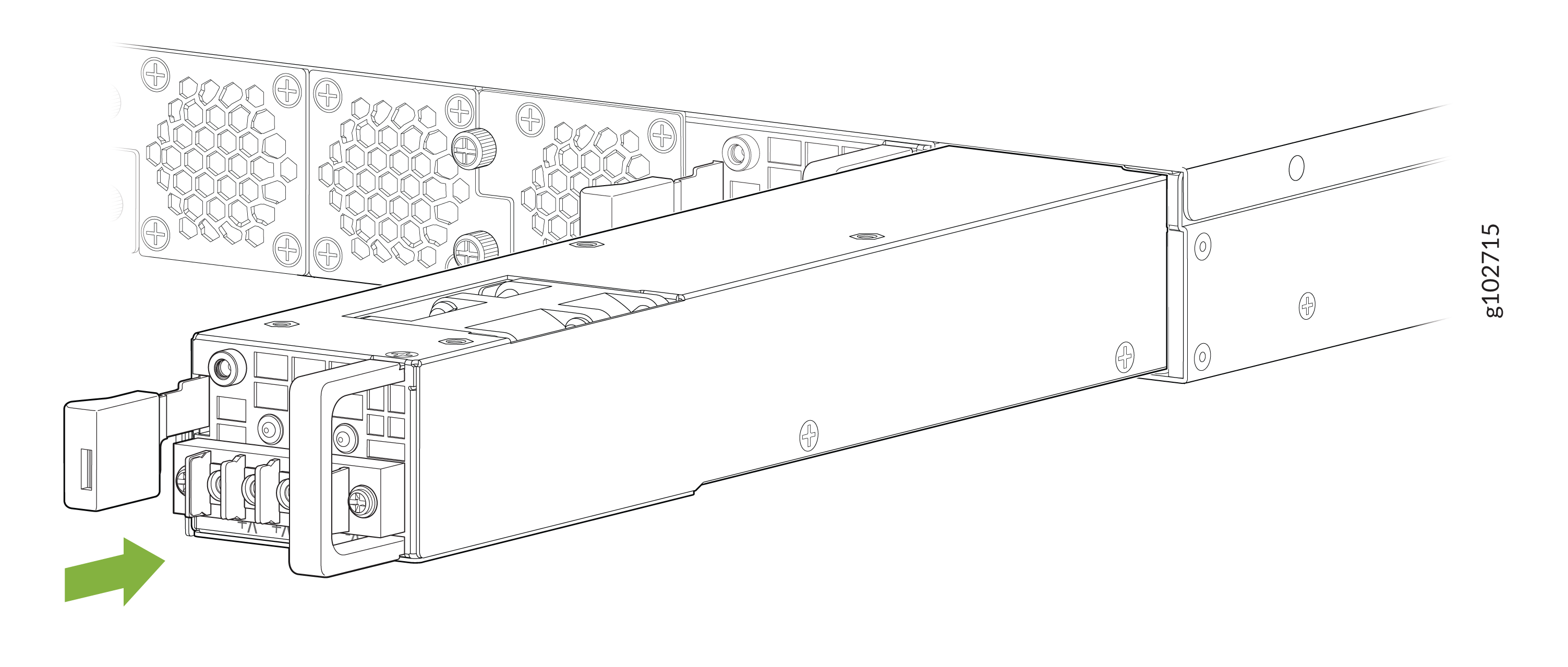

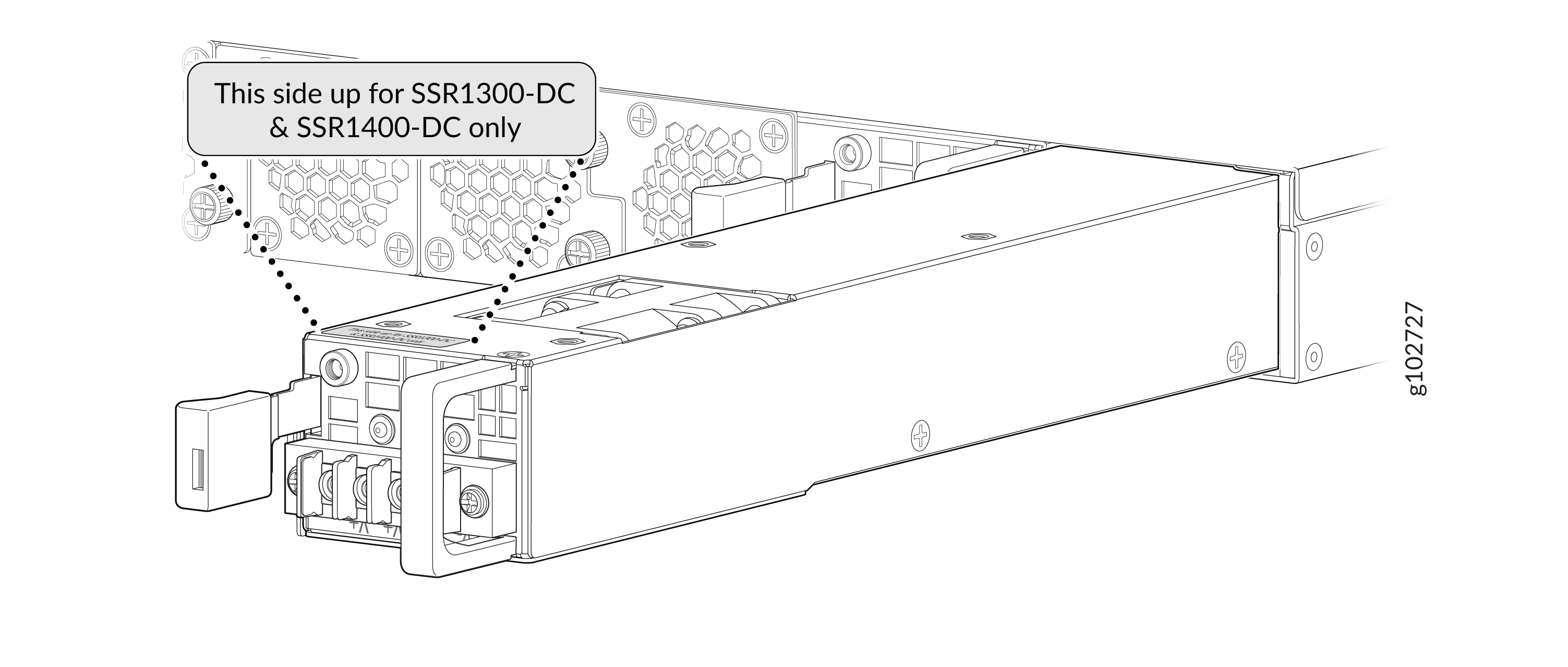

Use the following steps to install a DC power supply:

When installing a DC power supply in either an SSR1300-DC or an SSR1400-DC, the label indicating proper install orientation MUST be facing up, the orange handle must be on the RIGHT, and the locking lever must be on the LEFT as shown in the diagram below. If it is not installed in this orientation, it will not make proper electrical connection and could electrify the chassis.

If more than one power supply is being installed, turn on both power supplies at the same time.

If both power supplies are plugged in and receiving power, the RPS LED glows solid green.