ON THIS PAGE

PTX10004 Power Planning

Use the information in this topic to calculate the power consumption for the PTX10004 and plan your configuration’s power requirements.

Power Requirements for PTX10004 Components

Table 1 lists the power requirements for different hardware components of a PTX10004 router under typical voltage conditions and optics. For power requirements for chassis configurations, see Calculate Power Requirements for a PTX10004 Router.

The power management considers the values in the column titled 'Default Power Considered' in Table 1 to determine the power requirement when a new component is installed. You can disable the default power management by using the no-power-budget command.

|

Component |

Description |

Power Requirements (Watts) |

||

|---|---|---|---|---|

|

At 25° C |

At 46° C |

Default Power Considered |

||

|

JNP10004-SF3 |

PTX10004 SIB |

325 W |

350 W |

375 W |

|

JNP10004-FAN2 |

PTX10004 fan tray |

450 W |

650 W |

650 W |

|

JNP10004-FAN3 |

PTX10004 fan tray |

840 W |

840 W |

840 W |

|

Routing Engine |

PTX10004 enhanced RCB |

100 W |

150 W |

200 W |

|

PTX10K-LC1201-36CD |

36-port QSFP56-DD line card (without optical transceivers) |

If the router has Junos OS Evolved Release 21.4 or earlier installed in it |

2360 W |

|

|

976 W |

1008 W |

|||

|

If the router has Junos OS Evolved Release 22.1 or later installed in it |

||||

|

918 W |

948 W |

|||

|

PTX10K-LC1202-36MR |

36-port line card (thirty-two 100GbE ports and four 400GbE ports). |

740 W |

750 W |

1150 W |

Calculate Power Requirements for a PTX10004 Router

Use the Power Calculator or the information in this topic to calculate power requirements of your PTX10004 configuration and the number of power supplies required for different PTX10004 router configurations.

To ensure adequate power and to avoid raising a power alarm, we recommend that you maintain n +1 power supplies in your router at all times. Replace failed power supplies immediately to prevent unexpected failures.

If a new line card is installed in an operational router, power management does not power on the line card if the increased power demand exceeds the total available power, including redundant power. If redundant power is used to power on the line card, a minor alarm is raised, which becomes a major alarm if the condition is not corrected.

The calculations in this topic represent the maximum power requirements that you need to budget for your PTX10004 router configuration. The actual power consumption of your router will be less than the calculated results shown here and will vary based on the hardware and software configuration of your router, the amount of traffic passing through the line cards, and environmental variables such as room temperature.

Before you begin these calculations:

-

Ensure that you understand the different router configurations. See PTX10004 Components and Configurations.

-

Ensure that you know the power requirements of different router components. See Power Requirements for PTX10004 Components.

This topic describes these tasks:

- How to Calculate the Power Consumption of Your PTX10004 Configuration

- How to Calculate the Number of Power Supplies Required for Your PTX10004 Configuration

How to Calculate the Power Consumption of Your PTX10004 Configuration

Use the following procedure to determine the maximum power you need to supply to the router. To calculate maximum system power consumption, you first determine the combined maximum internal power requirements of all the router components and then divide this result by the power supply output power.

The calculations in this topic represent the maximum power requirements that you need to budget for your PTX10004 router configuration. The actual power consumption of your router will be less than the calculated results shown here and will vary based on the hardware and software configuration of your router, the amount of traffic passing through the line cards, and environmental variables such as room temperature.

To calculate maximum system power consumption:

How to Calculate the Number of Power Supplies Required for Your PTX10004 Configuration

The minimum power configuration for PTX10004 routers is three power supplies. However, using the calculated minimum power configuration doesn’t prevent the system from raising a power alarm. To ensure you don’t log power alarms with a fully loaded chassis, you must configure your router for dual feed and high-power settings.

To calculate the number of power supplies required for your minimum router configuration:

JNP10K-PWR-AC2 Power Specifications

The JNP10K-PWR-AC2 power supply supports AC, high-voltage alternating current (HVAC), and high-voltage direct current (HVDC).

Table 8 lists the power specifications for the AC power supply (JNP10K-PWR-AC2) used in a PTX10004 chassis.

|

Specification |

Value |

|---|---|

|

AC input voltage |

180–305 VAC |

|

DC input voltage |

190–410 VDC |

|

Input current rating |

28.5 A |

|

DC output power |

12.3 V, 5500 W with dual feed and 5000 W with single feed |

Table 9 shows the physical specifications for a JNP10K-PWR-AC2 power supply.

|

Specification |

Value |

|---|---|

|

Height |

3.5 in. (8.89 cm) |

|

Width |

3.6 in. (9.14 cm) |

|

Depth |

15.1 in. (38.35 cm) |

|

Weight |

11.4 lb (5.17 kg) |

JNP10K-PWR-AC3 Power Specifications

The JNP10K-PWR-AC3 power supply supports AC.

Table 10 lists the power specifications for the AC power supply (JNP10K-PWR-AC3) used in a PTX10004 chassis.

|

Specification |

Value |

|---|---|

|

AC input voltage |

180–264 VAC |

|

Input current rating |

16 A |

|

DC output power |

12.3 V |

Table 11 shows the physical specifications for a JNP10K-PWR-AC3 power supply.

|

Specification |

Value |

|---|---|

|

Height |

3.386 in. (8.60 cm) |

|

Width |

3.584 in. (9.10 cm) |

|

Depth |

17.15 (43.57 cm) |

|

Weight |

12.8 lbs (5.8 kg) |

JNP10K-PWR-AC3H Power Specifications

The JNP10K-PWR-AC3H power supply supports HVAC and HVDC.

Table 12 lists the power specifications for the HVAC and HVDC power supply (JNP10K-PWR-AC3H) used in a PTX10004 chassis.

|

Specification |

Value |

|---|---|

|

AC input voltage |

180–305 VAC (each feed) HVAC 190 – 410 VAC (each feed) HVDC |

|

Input current rating |

50 A |

|

DC output power |

12.3 V (HVAC) 12.9 V (HVDC) |

Table 13 shows the physical specifications for a JNP10K-PWR-AC3H power supply.

|

Specification |

Value |

|---|---|

|

Height |

3.386 in. (8.60 cm) |

|

Width |

3.584 in. (9.10 cm) |

|

Depth |

16.966 in (43.10 cm) |

|

Weight |

12.8 lbs (5.8 kg) |

PTX10004 Power Cable Specifications

Most sites distribute power through a main conduit that leads to frame-mounted power distribution panels, one of which can be located at the top of the rack that houses the router. An AC power cord connects each power supply to the power distribution panel.

In North America, AC power cords must not exceed 15 feet (approximately 4.5 meters) in length, to comply with National Electrical Code (NEC) Sections 400-8 (NFPA 75, 5-2.2) and 210-52 and Canadian Electrical Code (CEC) Section 4-010(3). The cords shipped with the router to North America and Canada are in compliance.

The PTX10004 AC, high-voltage alternating current (HVAC), and high-voltage direct current (HVDC) power supplies have specific cord requirements. Use the following sections to determine the cable requirements based on the model of your power supply and any mode settings:

-

For JNP10K-PWR-AC3 with 20-A input and 15-A input, see Table 14

-

For JNP10K-PWR-AC2 with 20-A input, see JNP10K-PWR-AC2 Power Cable Specifications.

-

For JNP10K-PWR-AC2 with 30-A input, see JNP10K-PWR-AC2 Power Cable Specifications for 30-A Input.

- JNP10K-PWR-AC3 Power Cable Specifications

- JNP10K-PWR-AC3H Power Cable Specifications

- JNP10K-PWR-AC2 Power Cable Specifications

- JNP10K-PWR-AC2 Power Cable Specifications for 30-A Input

JNP10K-PWR-AC3 Power Cable Specifications

The JNP10K-PWR-AC3 power supply operates in two modes:

-

20-A input with 7800 W or 6000 W or 3000 W output

-

15-A input with 7800 W or 6900 W, or 4600 W, or 2300 W output

When power cords with right angle plugs at the PSU end are selected, they must be in pairs of Right Angle Left Plugs for inputs A0 or B0 and Extended Right Angle Left Plugs for inputs A1 or B1.

See Table 14 for a list of appropriate cables.

Do not run JNP10K-PWR-AC3 power supplies using 16-A or 20-A cables if connected to 15-A input.

You can prevent AC power cables from being exposed to hot air exhaust by always routing the power cables away from the fan trays and power supplies.

With right angle power cords and the baffle installed, the power cords will be exposed to hot exhaust air. The IEC C21 plugs have a temperature rating of 155C and the power cord cables have a rating of 90C.

|

Locale |

Cord Set Rating |

Plug Standard |

Spare Juniper Model Number |

Graphic |

|---|---|---|---|---|

| Straight Plug at PSU Input | ||||

|

Australia and New Zealand |

15 A, 250 VAC | AS/NZS 3112 |

CBL-PWRC21-AU |

|

|

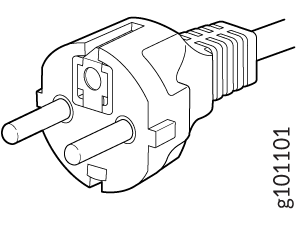

Europe (except Italy, Switzerland, and United Kingdom) |

16A, 250 VAC | CEE 7/7 |

CBL-PWRC21-EU |

|

|

Italy |

16A, 250 VAC | CEI 23-16 |

CBL-PWRC21-IT |

|

|

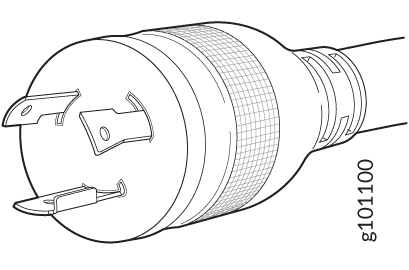

North America |

20A, 250 VAC |

Locking NEMA L6-20P |

CBL-PWRC21-US-L |

|

| NEMA 6-20P |

CBL-PWRC21-US |

|

||

| International | 16A, 250VAC |

IEC-309 316P6W |

CBL-PWRC21-316P6 |

|

| North America | 20A, 250 VAC |

IEC-309 320P6W |

CBL-PWRC21-320P6 |

|

| Japan | 20A, 250 VAC | NEMA L6-20P |

CBL-PWRC21-JP-L |

|

| China | 16A, 250 VAC | GB2099-1 |

CBL-PWRC21-CN |

|

| North America | 20A, 250 VAC | IEC-320-C20 |

CBL-PWRC21-C20-NA |

|

| Europe | 16A, 250 VAC | IEC-320-C20 |

CBL-PWRC21-C20-EU |

|

| Japan | 20A, 250 VAC | IEC-320-C20 |

CBL-PWRC21-C20-JP |

|

| China | 16A, 250 VAC | IEC-320-C20 |

CBL-PWRC21-C20-CN |

|

| Switzerland | 16A, 250 VAC | SEV1011 |

CBL-PWRC21-SZ |

|

| South Africa | 16A, 250 VAC |

RA SANs 164/1 |

CBL-PWRC21-SA |

|

| India | 16A, 250VAC | RA IS 1293 |

CBL-PWRC21-IN |

|

| United Kingdom | 16A, 250 VAC | BS 1363 |

CBL-PWRC21-UK |

|

| Israel | 16A, 250 VAC |

SI 32/1971 Type IL/3G |

CBL-PWRC21-IL |

|

| Brazil | 16A, 250 VAC |

NBR 14136 Type BR/3 |

CBL-PWRC21-BR |

|

| Argentina | 16A, 250 VAC |

IRAM 2073 Type RA/3 |

CBL-PWRC21-AR |

|

| Right Angle Left Plug at PSU Input | ||||

| USA | 20A, 250 VAC | NEMA L6-20P | CBL-PWRC21R-US-L |

|

| USA | 20A, 250 VAC | NEMA 6-20P | CBL-PWRC21R-US |

|

| Europe | 16A, 250 VAC | CEE 7/7 | CBL-PWRC21R-EU |

|

| Australia | 15A, 250 VAC | AS/NZ 3112 | CBL-PWRC21R-AU |

|

| Italy | 16A, 250 VAC | CEI 23-50 | CBL-PWRC21R-IT |

|

| International | 16A, 250 VAC |

IEC 60309 316P6W |

CBL-PWRC21R-316P6 | |

| North America | 16A, 250VAC |

IEC 60309 320P6W |

CBL-PWRC21R-320P6 | |

| Japan | 20A, 250 VAC | NEMA L6-20P | CBL-PWRC21R-JP-L |

|

| China | 16A, 250 VAC | GB2099-1 | CBL-PWRC21R-CN |

|

| North America | 16A, 250 VAC |

IEC-60320 C20 |

CBL-PWRC21R-C20-NA |

|

| Europe | 16A, 250 VAC |

IEC 60320 C20 |

CBL-PWRC21R-C20-EU |

|

| Japan | 20A, 250 VAC |

IEC 60320 C20 |

CBL-PWRC21R-C20-JP |

|

| China | 16A, 250 VAC |

IEC 60320 C20 |

CBL-PWRC21R-C20-CN |

|

| Switzerland | 16A, 250 VAC | SEV 1011 | CBL-PWRC21R-SZ | |

| South Africa | 16A, 250 VAC | SANS 164/1 | CBL-PWRC21R-SA |

|

| India | 16A, 250 VAC | IS 1293, RA | CBL-PWRC21R-IN |

|

| United Kingdom | 16A, 250 VAC | BS1363 | CBL-PWRC21R-UK |  |

| Israel | 16A, 250 VAC |

SI 32/1971 TYPE IL/3G |

CBL-PWRC21R-IL |

|

| Brazil | 16A, 250 VAC |

NBR 14136 TYP BR/3 |

CBL-PWRC21R-BR |

|

| Argentina | 16A, 250 VAC |

IRAM 2073 TYPE RA/3 |

CBL-PWRC21R-AR |

|

| Extended Right Angle Left Plug at PSU Input | ||||

| USA | 20A, 250 VAC | NEMA L6-20P | CBL-PWRC21RL-US-L |

|

| USA | 20 A, 250 VAC | NEMA 6-20P | CBL-PWRC21RL-US |

|

| Europe | 16A, 250 VAC | CEE 7/7 | CBL-PWRC21RL-EU |

|

| Australia | 15A, 250 VAC | AS/NZ 3112 | CBL-PWRC21RL-AU |

|

| Italy | 16A, 250 VAC | CEI 23-50 | CBL-PWRC21RL-IT |

|

| International | 16A, 250 VAC |

IEC-60309 316P6W |

CBL-PWRC21RL-316P6 | |

| North America | 20A, 250 VAC |

IEC-60309 320P6W |

CBL-PWRC21RL-320P6 | |

| Japan | 20A, 250 VAC | NEMA L6-20P | CBL-PWRC21RL-JP-L |

|

| China | 16A, 250 VAC | GB2099-1 | CBL-PWRC21RL-CN |

|

| North America | 20A, 250 VAC |

IEC-60320 C20 |

CBL-PWRC21RL-C20NA |

|

| Europe | 16A, 250 VAC |

IEC-60320 C20 |

CBL-PWRC21RL-C20EU |

|

| Japan | 20A, 250 VAC |

ICE-60320 C20 |

CBL-PWRC21RL-C20JP |

|

| China | 16A, 250 VAC |

IEC-60320 C20 |

CBL-PWRC21RL-C20CN |

|

| Switzerland | 16A, 250 VAC | SEV 1011 | CBL-PWRC21RL-SZ | |

| South Africa | 16A, 250 VAC | SANS 164/1 | CBL-PWRC21RL-SA |

|

| India | 16A, 250 VAC | IS1293, RA | CBL-PWRC21RL-IN |

|

| United Kingdom | 16A, 250 VAC | BS 1363 | CBL-PWRC21RL-UK |  |

| Israel | 16A, 250 VAC |

SI 32/1971 Type IL/3G |

CBL-PWRC21RL-IL |

|

| Brazil | 16A, 250 VAC |

NBR 14136 Type BR/3 |

CBL-PWRC21RL-BR |

|

| Argentina | 16A, 250 VAC |

IRAM 2073 Type RA/3 |

CBL-PWRC21RL-AR |

|

JNP10K-PWR-AC3H Power Cable Specifications

The power supply unit takes four single-phase HVAC (180-305 VAC) or HVDC (190 - 410VDC) inputs (A0, A1, B0, and B1) at either 20 A or 15 A and provides a DC output of 12.3V.

-

20-A input with 7800 W or 6000 W or 3000 W output

-

15-A input with 7800 W or 7500 W, or 5000 W, or 2500 W output

When power cords with right angle plugs at the PSU end are selected, they must be in pairs of Right Angle Left Plugs for inputs A0 or B0 and Extended Right Angle Left Plugs for inputs A1 or B1.

See Table 15 for a list of appropriate cables.

Do not run JNP10K-PWR-AC3H power supplies using 16-A or 20-A cables if connected to 15-A input.

You can prevent the power cables from being exposed to hot air exhaust by always routing the power cables away from the fan trays and power supplies.

With right angle power cords and the baffle installed, the power cords will be exposed to hot exhaust air. The IEC C21 plugs have a temperature rating of 155C and the power cord cables have a rating of 90C.

|

Locale |

Cord Set Rating |

Plug Standard |

Spare Juniper Model Number |

Graphic |

|---|---|---|---|---|

| Straight Plug at PSU Input | ||||

|

North America |

16 A, 250 VAC |

Locking NEMA L6-20P |

CBL-JNP-SG4-US-L |

|

|

NEMA 6-20P |

CBL-JNP-SG4-US |

|

||

| Japan | 20A, 250V | NEMA L6-20P to APP400 | CBL-JNP-SG4-JPL | |

| Italy | 16A, 250V | CEI 23-50 | CBL-JNP-SG4-IT |

|

| Australia and New Zealand | 15A, 250V | AS/NZ 3112 | CBL-JNP-SG4-AU |

|

| Europe (continental) | 16A, 250V | CEE 7/7 | CBL-JNP-SG4-EU |

|

| Straight Plug | 16A, 250V | IEC309-316P6W | CBL-JNP-SG4-316P6W | |

| US/Canada | 16A, 250V | IEC309-320P6W | CBL-JNP-SG4-320P6W | |

| China | 16A, 250V | GB2099-1 | CBL-JNP-SG4-CH |

|

| Europe-China-Japan | 16A, 250V | IEC320-C20 | CBL-JNP-SG4-C20-CH |

|

| Switzerland | 16A, 250V | SEV1011 | CBL-JNP-SG4-SZ |

|

| Japan/US/Canada | 20A, 250V | NEMA 6-20P | CBL-JNP-SG4-US |

|

| South Africa/India | 16A, 250V | SANS 164/1 | CBL-JNP-SG4-SA |

|

| UK | 13A, 250V | BS1363 | CBL-JNP-SG4-UK |  |

| Israel | 16A, 250V | SI 32/1971 Type IL/3C | CBL-JNP-SG4-IL |

|

| Brazil | 16A, 250V | NBR 14136 Type BR/3 | CBL-JNP-SG4-BR |

|

| Argentina | 16A, 250V | IRAM 2073 Type RA/3 | CBL-JNP-SG4-AR |

|

| Straight Plug | 15A, 277V | NEMA L7-20P | CBL-JNP-SG4-HVAC |

|

| Taiwan | 16A, 250V | CNS 690 6/20 | CBL-JNP-SG4-TW | |

| India | 16A, 250V | RA IS 1293 | CBL-JNP-SG4-IN | |

| Right Angle Left Plug at PSU Input | ||||

| Bare Wire | 20A, 600V | Bare Wire | CBL-JNP-SG4R-BARE | |

| North America | 20A, 300V | NEMA L6-20P | CBL-JNP-SG4RA-US-L | |

| Japan | 20A, 250V | NEMA L6-20P | CBL-JNP-SG4RA-JPL | |

| North America | 20A, 300V | IEC320-C20 | CBL-JNP-SG4RA-C20 | |

| Italy | 16A, 250V | CEI 23-50 | CBL-JNP-SG4RA-IT | |

| Australia/New Zealand | 15A, 250V | AS/NZ 3112 | CBL-JNP-SG4RA-AU | |

| Continental Europe | 16A, 250V | CEE 7/7 | CBL-JNP-SG4RA-EU | |

| RA-Left | 16A, 250V | IEC309-316P6W | RA-Left | |

| US/Canada | 16A, 250V | IEC309-320P6W | CBL-JNP-SG4RA-320P | |

| China | 16A, 250V | GB2099-1 | CBl-JNP-SG4RA-CH | |

| Switzerland | 16A, 250V | SEV1011 | CBL-JNP-SG4RA-SZ | |

| US/Canada | 20A, 250V | NEMA 6-20P | CBL-JNP-SG4RA-US | |

| South Africa/India | 16A, 250V | SANS 164-1 | CBL-JNP-SG4RA-SA | |

| UK | 13A, 250V | BS1363 | CBL-JNP-SG4RA-UK | |

| Israel | 16A, 250V | SI 32/1971 Type IL/3C | CBL-JNP-SG4RA-IL | |

| Brazil | 16A, 250V | NBR 14136 Type BR/3 | CBL-JNP-SG4RA-BR | |

| Argentina | 16A, 250V | IRAM 2073 Type RA/3 | CBL-JNP-SG4RA-AR | |

| RA-Left Plug | 15A, 277V | NEMA L7-20P | ||

| Extended Right Angle Left Plug at PSU Input | ||||

| RA-Left | 20A, 600V | Bare Wire | CBL-SG4RL-BARE | |

| North America | 20 A, 300V | NEMA L6-20P | CBL-JNP-SG4RL-US-L | |

| Japan | 20A, 250V | NEMA L6-20P | CBL-JNP-SG4RL-JPL | |

| North America | 20 A, 300V | IEC320-C20 | CBL-JNP-SG4RL-C20 | |

| Italy | 16A, 250V | CEI 23-50 | CBL-JNP-SG4RL-IT | |

| Australia/New Zealand | 15A, 250V | AS/NZ 3112 | ||

| Continental Europe | 16A, 250V | CEE 7/7 | CBL-JNP-SG4RL-EU | |

| AC | 16A, 250V | IEC309-316P6W | CBL-JNP-SG4RL-316P6 | |

| US/Canada | 16A, 250V | IEC309-320P6W | CBL-JNP-SG4RL-320P6 | |

| China | 16A, 250V | GB2099-1 | CBl-JNP-SG4RL-CH | |

| Switzerland | 16A, 250V | SEV1011 | CBL-JNP-SG4RL-SZ | |

| Japan/US/Canada | 20A, 250V | NEMA 6-20P | CBL-JNP-SG4RL-US | |

| South Africa/India | 16A, 250V | SANS 164/1 | CBL-JNP-SG4RL-SA | |

| UK | 13A, 250V | BS1363 | CBL-JNP-SG4RL-UK | |

| Israel | 16A, 250V | SI 32/1971 Type IL/3C | CBL-JNP-SG4RL-IL | |

| Brazil | 16A, 250V | NBR 14136 Type BR/3 | CBL-JNP-SG4RL-BR | |

| Argentina | 16A, 250V | IRAM 2073 Type RA/3 | CBL-JNP-SG4RL-AR | |

| HVAC | 15A, 277V | NEMA L7-20P | CBL-JNP-SG4RL-HVAC | |

JNP10K-PWR-AC2 Power Cable Specifications

The JNP10K-PWR-AC2 power supply operates in two modes:

-

20-A input with 3000-W output; see Table 16 for a list of appropriate cables. One end of the cable has a type SAF-D-GRID Series (3-5958P4) Anderson APP-400 connector, rated 30A/400V/105C. An example of the connector is shown in Figure 1.

-

30-A input with 5500-W output; see JNP10K-PWR-AC2 Power Cable Specifications for 30-A Input for a list of appropriate cables and connectors for 30-A input. One end of the cable has a type SAF-D-GRID Series (3-5958P4) Anderson APP-400 connector, rated 30A/400V/105C, while the other end of the cable is bare wire.

Do not run JNP10K-PWR-AC2 power supplies using 16-A or 20-A cables if connected to 30-A input.

You can prevent AC power cables from being exposed to hot air exhaust by always routing the power cables away from the fan trays and power supplies.

|

Locale |

Cord Set Rating |

Plug Standard |

Spare Juniper Model Number |

Graphic |

|---|---|---|---|---|

|

Argentina |

16 A, 250 VAC |

IRAM 2073 Type RA/3 |

CBL-JNP-SG4-AR |

|

|

Australia and New Zealand |

15 A, 250 VAC |

AS/NZS 3112 |

CBL-JNP-SG4-AU |

|

|

Brazil |

16 A, 250 VAC |

NBR 14136 Type BR/3 |

CBL-JNP-SG4-BR |

|

|

China |

16 A, 250 VAC |

GB2099 |

CBL-JNP-SG4-CH |

|

|

China, Europe, and Japan |

16 A, 250 VAC |

C20 to Anderson 3-5958p4 |

CBL-JNP-SG4-C20-CH |

|

|

Europe (except Italy, Switzerland, and United Kingdom) |

20 A, 250 VAC |

CEE 7/7 |

CBL-JNP-SG4-EU |

|

|

Great Britain |

13 A, 250 VAC |

BS1363 |

CBL-JNP-SG4-UK |

|

|

India |

16 A, 250 VAC |

SANS 164/1 |

CBL-JNP-SG4-SA |

|

|

Israel |

16 A, RA, 250 VAC |

SI 32/1971 Type IL/3C |

CBL-JNP-SG4-IL |

|

|

Italy |

16 A, 250 VAC |

CEI 23-16 |

CBL-JNP-SG4-IT |

|

|

North America |

20 A, 250 VAC |

3-5958P4 to IEC 60320 C20 |

CBL-JNP-SG4-C20 |

|

|

16 A, 250 VAC |

Locking NEMA L6-20P |

CBL-JNP-SG4-US-L |

|

|

|

NEMA 6-20P |

CBL-JNP-SG4-US |

|

||

|

20 A, 277 V |

NEMA I7-20P |

CBL-JNP-SG4-HVAC |

|

|

|

South Africa |

16 A, 250 VAC |

SANS 164/1 |

CBL-JNP-SG4-SA |

|

|

Switzerland |

16 A, 250 VAC |

CEI 23-50 |

CBL-JNP-SG4-SZ |

|

JNP10K-PWR-AC2 Power Cable Specifications for 30-A Input

The JNP10K-PWR-AC2 AC or HVDC power supplies require a high-current cable assembly when set for 30-A input. One end of the cable has a type SAF-D-GRID Series (3-5958P4) Anderson APP-400 connector, rated 30A/400V/105C, while the other end of the cable is bare wire. See Figure 2 and Table 17. These cables are separately orderable and are not shipped automatically with JNP10K-PWR-AC2 orders. An example of the right-angle cable and connector is shown in Figure 4.

For connection to AC systems, Juniper provides a cable with either a NEMA 30-A connector (Figure 2) or an IEC 330P6W connector (Figure 3).

|

Option |

Locale |

Cord Set Rating |

Plug Standards |

Connector |

Spare Juniper Model Number |

|---|---|---|---|---|---|

|

AC/HVDC power cord |

Any |

30 A 400 VAC |

UL 950 and IEC 60950 |

Anderson/straight to bare wire |

CBL-PWR2-BARE |

|

Any |

30 A 400 VAC |

UL 950 and IEC 60950 |

Anderson/right-angle to bare wire |

CBL-PWR2-BARE-RA |

|

|

AC power cord |

Continental Europe |

30 A 250 VAC |

UL 950 and IEC332P6 |

Anderson/right-angle to IEC 332P6 |

CBL-PWR2-332P6W-RA |

|

Continental Europe |

30 A 250 VAC |

UL 950 and IEC332P6 |

Anderson/straight to IEC332P6 |

CBL-PWR2-332P6W |

|

|

North America |

30 A 250 VAC |

IEC330P6 |

Anderson/right-angle to IEC 330P6 |

CBL-PWR2-330P6W-RA |

|

|

North America |

30 A 250 VAC |

IEC330P6 |

Anderson/straight to IEC 330P6 |

CBL-PWR2-330P6W |

|

|

North America |

30 A 250 VAC |

UL 498 and CSA |

Anderson/right-angle to L6-30P (NEMA-30A) |

CBL-PWR2-L6-30P-RA |

|

|

North America |

30 A 250 VAC |

UL 498 and IEC5958P4 |

Anderson/straight to L6-30P (NEMA-30A) |

CBL-PWR2-L6-30P |

|

|

AC jumper power cord |

Any |

30 A 400 VAC |

UL and CSA |

Anderson/straight to Anderson |

CG-CBL-APP-400-02 |

1 — Black wire –“+” or “-” for HVDC and “Hot or neutral” for AC | 3 — White wire – “+” or “-” for HVDC and “Hot or neutral” for AC |

2 — Green wire - Ground |

JNP10K-PWR-DC2 Power Specifications

Table 18 lists the power specifications for the high-voltage direct current (HVDC) power supply used in PTX10004 routers.

|

Item |

Specifications |

|---|---|

|

DC input voltage |

|

|

DC input current rating |

|

|

Output power |

|

Table 19 shows the physical specifications for a JNP10K-PWR-DC2 power supply.

|

Specification |

Value |

|---|---|

|

Height |

3.5 in. (8.89 cm) |

|

Width |

3.6 in. (9.14 cm) |

|

Depth |

16.05 in. (40.77 cm) |

|

Weight |

8.1 lb (3.67 kg) |

JNP10K-PWR-DC3 Power Specifications

Table 20 lists the power specifications for the DC power supply (JNP10K-PWR-DC3) used in PTX10004 routers.

|

Item |

Specifications |

|---|---|

|

DC input voltage |

|

|

Input current rating |

60 A/80 A |

|

Output power |

12.3 VDC |

Table 21 shows the physical specifications for a JNP10K-PWR-DC3 power supply.

|

Specification |

Value |

|---|---|

|

Height |

3.386 in. (8.60 cm) |

|

Width |

3.584 in. (9.10 cm) |

|

Depth |

15.391 in. (39.09 cm) |

|

Weight |

12.8 lb. (5.7 kg) |

PTX10004 Grounding Cable and Lug Specifications

The router must be adequately grounded before power is connected to ensure proper operation and to meet safety and electromagnetic interference (EMI) requirements. To ground a PTX10004 chassis, connect a grounding cable to earth ground and then attach it to the chassis grounding point on the rear of the chassis beneath.

You must install the PTX10004 in a restricted-access location and ensure that the chassis is always properly grounded. The PTX10004 has a two-hole protective grounding terminal provided on the chassis. Under all circumstances, use this grounding connection to ground the chassis. For AC-powered systems, you must also use the grounding wire in the AC power cord along with the two-hole grounding lug connection. This tested system meets or exceeds all applicable EMC regulatory requirements with the two-hole protective grounding terminal.

To comply with GR-1089 requirements, all intrabuilding copper cabling used for SFP+, QSFP+, and higher must be shielded and grounded at both ends.

Before router installation begins, a licensed electrician must attach a cable lug to the grounding cables that you supply. See Connect the PTX10004 Router to Earth Ground. A cable with an incorrectly attached lug can damage the router.

Before you connectthe router to earth ground, review the following information:

-

Two threaded inserts (PEM nuts) are provided on the lower rear of the chassis to connect the router to earth ground. The protective earthing terminals are spaced at 0.63 in. (16 mm) centers.

-

The grounding lug required is a Panduit LCD6-10A-L or equivalent (provided). The grounding lug accommodates 6 AWG (13.3 mm²) stranded wire. If one or more JNP10K-PWR-DC2 power supplies are installed in the chassis and set for high input (80 A), use the Panduit LCD4-14A-L or equivalent (provided). This lug accommodates 4 AWG (21.1mm²) stranded wire. The 4 AWG (21.1 mm²) stranded wire should be rated 90° C or as permitted by local electrical code.

-

The grounding cable that you provide for a PTX10004 must be the same size as, or heavier than, the input wire of each power supply. Minimum recommendations are 6 AWG (13.3 mm²) stranded copper wire, Class B; 90° C wire, or as permitted by local code.