ON THIS PAGE

MX2008 Chassis

MX2008 Chassis Description

The router chassis is a rigid sheet metal structure that houses all the other router components (see Figure 1, Figure 2, and Figure 3). The MX2008 Universal Routing Platform with standard cable managers and EMI cover measures 42 in. (106.68 cm) high, 19 in. (48.26 cm) wide, and 30.90 in. (78.49 cm) deep (from the front-mounting flanges to the rear of the chassis). An extended cable manager extends the total depth to 36.82 in. (93.53 cm). The chassis can be installed in a standard 19-in. open-frame or four-post rack, or an enclosed cabinet.

There must be a minimum of 24 rack units (U) of usable rack space when installing the MX2008 router into a rack.

If you are installing the MX2008 router into a network cabinet, make sure that no hardware, device, rack, or cabinet component obstructs the 24 U rack space from access during installation.

The chassis includes the following features (see Figure 1, Figure 2, and Figure 3).

-

Front-mounting flanges for mounting in a four-post rack or cabinet.

-

Center-mounting metal brackets for center-mounting in an open-frame rack (optional).

Before removing or installing components, attach an electrostatic discharge (ESD) strap to an ESD point, and place the other end of the strap around your bare wrist. Failure to use an ESD strap could result in damage to the hardware components.

The router must be connected to earth ground during normal operation.

The MX2008 router is 24 rack units (U) tall. One router can be installed in an open-frame rack, four-post rack, or cabinet. The MX2008 router has 10 dedicated line-card slots, which means a maximum of 10 Modular Port Concentrators (MPCs) including adapter cards and Modular Interface Cards (MICs) can be installed on MX2008. ADCs provide housing to MPCs. The MPCs attach to the adapter cards, which in turn connect to the backplane. Up to 2 MICs can be installed in each MPC. Fully populated, the MX2008 router supports up to 20 MICs. The MX2008 host subsystem consists of two Routing and Control Boards (RCBs). The RCB is an integrated board and a single FRU that provides Routing Engine and Control Board functionality and supports virtualization. The router contains 8 SFBs that provide 7+1 redundancy.

One router can be installed in a 24 U or taller open-frame or four-post rack if the rack can support the combined weight, which can be greater than 664.8 lb (301.55 kg).

The dimensions also include the cable managers and EMI cover.

Remove field-replacement units (FRUs) from the front of the MX2008 router before you install the router.

See Table 1 for information about the components on the front of the MX2008 router.

|

Component No. |

Component Description |

Slots |

Number of FRUs |

|---|---|---|---|

|

1 |

Craft interface |

– |

1 |

|

2 |

Enhanced Switch Fabric Board (SFB2) |

0 through 7 |

8 |

|

3 |

Routing and Control Boards (RCB) |

0 and 1 |

2 |

|

4 |

MPCs (with MICs installed) |

0 through 9 |

10 |

|

5 |

Cable manager |

– |

1 |

See Table 2 for information about components on the back of an AC-powered MX2008 router.

|

Component No. |

Component Description |

Slots |

Number of FRUs |

|---|---|---|---|

|

1 |

AC PDM—Three-phase delta or wye, or a single-phase AC PDM, or a high-voltage second-generation universal (HVAC/HVDC) PDM |

PDM1/Input1 |

1 |

|

2 |

AC PSMs or high-voltage second-generation universal (HVAC/HVDC) PSMs |

0 through 8 |

9 |

|

3 |

PSM air filter |

– |

1 |

|

4 |

AC PDM—Three-phase delta or wye, or a single-phase AC PDM, or a high-voltage second-generation universal (HVAC/HVDC) PDM |

PDM0/Input0 |

1 |

|

5 |

Fan tray air filter |

– |

1 |

|

6 |

Fan trays (two) |

Fan tray 0 and fan tray 1 (behind access door) |

2 |

Remove field-replacement units (FRUs) from the rear of the MX2008 router before you install the router.

Remove field replacement units (FRUs) from the rear of the MX2008 router before you install the router.

See Table 3 for information about router components on the back of a DC-powered MX2008 router.

|

Component No. |

Component Description |

Slots |

Number of FRUs |

|---|---|---|---|

|

1 |

DC PDM, a DC PDM (240 V China), or a high-voltage second-generation universal (HVAC/HVDC) PDM |

PDM1/Input1 |

1 |

|

2 |

DC PSMs, DC PSMs (240 V China), or high-voltage second-generation universal (HVAC/HVDC) PSMs |

0 through 8 |

9 |

|

3 |

PSM air filter |

– |

1 |

|

4 |

DC PDM, a DC PDM (240 V China), or a high-voltage second-generation universal (HVAC/HVDC) PDM |

PDM0/Input0 |

1 |

|

5 |

Fan tray air filter |

– |

1 |

|

6 |

Fan trays (two) |

Fan tray 0 and fan tray 1 (behind access door) |

2 |

Remove field replacement units (FRUs) from the rear of the MX2008 router before you install the router.

The MX2008 router has two ESD points. These are located on either side of the MPCs on the front of the chassis (see Figure 4).

See Also

MX2008 Backplane Description

The MX2008 router consist of a signal backplane and a power backplane that connect PSMs and PDMs to the chassis. The adapter cards are carrier cards used to house the MPCs. The MPCs install into the bottom card-cage signal backplanes from the front of the chassis and mate to the signal backplane to connect to the Enhanced Switch Fabric Boards (SFB2s) and the Routing and Control Boards (RCBs). The backplane connects 10 line cards to 8 SFBs and 2 RCBs. The SFBs and RCBs are installed at the top of the chassis from the front. The cooling system components also connect to the signal backplane. The PSMs install into the power backplane, and the PDMs mate to the power backplane.

The backplanes performs the following major functions:

Data path—Data packets are transferred across the signal backplane between the MPCs through the fabric ASICs on the SFBs.

Power distribution—The router PDMs relay power from the feeds to the input of the PSMs through the power backplane. In addition, the output power from PSMs is distributed to the components of the chassis (MPCs, SFBs, and RCBs), using the power backplane.

Control/management path—The backplanes provides management and control path connectivity among the various system components.

See Also

MX2008 Component Redundancy

A fully configured router is designed so that no single point of failure can cause the entire system to fail. Only a fully configured router provides complete redundancy. All other configurations provide partial redundancy. The following major hardware components are redundant:

Host subsystem—The host subsystem consists of two Routing and Control Boards (RCBs). The RCB is an integrated board and a single FRU that provides Routing Engine and Control Board functionality. The router can have one or two host subsystems. If two host subsystems are installed, one functions as the primary and the other functions as the backup. If the primary host subsystem (or either of its components) fails, the backup can take over as the primary.

DC power system—The MX2008 DC power system (-48 V and 240 V China) is made up of three components: nine power supply modules (PSMs), two power distribution modules (PDMs), and a power midplane. For telecom (48 VDC) power supplies the power system distributes power from a pool of 22.5 KW (20 KW for non-redundant PSMs and 2.5 KW reserved for PSM redundancy). This pool provides power to the whole chassis including the ten line-card slots, two fan trays, and critical FRUs. These critical FRUs consist of two RCBs and eight SFBs located in the top portion of the chassis.

Power distribution modules (PDMs)—In the DC configuration, each system provides N+1 PSM redundancy along with N+N feed redundancy. The power feeds from different sources need to be connected to different PDMs. If feeds that connect to one PDM fail in a redundant configuration, the other feed starts to provide full power.

Note:Depending on the voltage of the DC feeds, power can be drawn from both feeds. The feed with higher voltage provides more power. If the difference between the voltages is sufficient, then the higher voltage feed provides all the power. When the voltages are exactly the same, equal power is drawn from both feeds.

A total of two PDMs can be installed into a router. Each DC PDM operates with up to nine separate feeds of either 60-A or 80-A current limit. The 240 V China DC PDMs have nine feeds and do not have a switch selection. The capacity of these feeds is relayed to system software through a switch located on the DC PDM.

The MX2008 router supports two types of three-phase power system PDMs. The three-phase delta and three-phase wye. Individual phases are taken from three-phase feeds to individual PSMs. One feed provides power to six PSMs, while the second input feed provides power to the remaining three PSMs (supporting a total of nine PSMs).

DC power feed redundancy—The MX2008 DC power system is feed redundant. Each PSM can be connected to two separate feeds from different sources that are used to provide feed redundancy. There are two PDMs per power subsystem that carry nine feeds each. Feeds from one power source must be connected to one PDM and feeds from the other power source must be connected to the second PDM of the power subsystem (see Figure 5).

Figure 5: DC Power System Feed Redundancy

Each PSM has a set of two DIP switches located on the faceplate. These DIP switches are used to indicate whether a user wants to connect one feed to the power system, two feeds, or none. These DIP switches provide critical information to the power management system to help generate alarms in case of a feed failure or a wrong connection. Each PDM has an LED per feed indicating whether the feed is active or not, or whether the feed is connected properly. See MX2008 DC Power Supply Module (-48 V) Description.

Universal power system—The MX2008 supports connection of a high-voltage second-generation universal (HVAC/HVDC) power system.

High-Voltage Second-Generation Universal (HVAC/HVDC) PDMs—The universal PDM accepts either an HVAC or HVDC input. You can install a total of two PDMs into a router. Each universal PDM operates with nine feeds of a 30-A current limit. Each universal PSM is capable of delivering 3400 W of power with-dual feeds and 3000 W of power with a single-feed. In this configuration, each subsystem provides N+1 output PSM redundancy along with N+N feed redundancy. The power feeds from different sources need to be connected to different PDMs. If feeds that connect to one PDM fail in a redundant configuration, the other feed provides full power. For high-voltage second-generation universal (HVAC/HVDC) power system, both input power feeds are active and share the load when present.

Figure 6 illustrates the power distribution from the universal (HVAC/HVDC) PDMs to the universal (HVAC/HVDC) PSMs.

Figure 6: MX2010 Router Universal (HVAC/HVDC) Power Subsystem Feed Redundancy

AC power system—The MX2008 supports connection of three-phase and single-phase AC power systems.

There are two types of three-phase power systems: the three-phase delta and three-phase wye. The AC power going to the PSMs is split into three individual phases—each PSM works on a single phase. This means the power system works independent of the kind of AC feed is connected. You can connect one or two feeds, depending on the power system configuration (number of PSMs, redundancy, and so on). Each phase from each of the two feeds is distributed among one or two PSMs (one feed has each phase going to two PSMs, and the other feed has each phase going to a single PSM). See Figure 8 and Figure 9.

The single-phase AC PDM provides an AC input power interface to the PSM through the system power midplane. Up to nine PSMs can be connected to a single-phase AC PDM. Each single-phase AC PDM accepts seven or nine AC power cords from a single-phase AC source. Each AC input is independent and feeds one PSM. See Figure 7.

Figure 7: Power Distribution from Single-Phase Feed Delta PDM to the AC PSMs Figure 8: Power Distribution from Three-Phase Feed Delta PDM to the AC PSMs

Figure 8: Power Distribution from Three-Phase Feed Delta PDM to the AC PSMs Figure 9: Power Distribution from Three-Phase Feed Wye PDM to the AC PSMs

Figure 9: Power Distribution from Three-Phase Feed Wye PDM to the AC PSMs

The AC power system is feed redundant—each PSM takes in two AC feeds and uses one of the two. One AC feed is active at a time. If one feed fails, the PSM automatically switches over to the other feed without disrupting system function (see MX2008 AC Power Supply Module Description).

AC power requirements—Table 4 shows the MX2008 current requirements for the three-phase delta and wye power feeds.

Table 4: AC PDM Delta and Wye Current Requirements Three-Phase Voltage

Input Feed

Current Delta per Three-Phase PDM

Current Wye per Three-Phase PDM

200 V (minimum–nominal) (line-to-line) for delta (per phase)

1

50 A

–

2

25 A

–

200 V (minimum–nominal) (line-to-neutral) for wye (per phase)

1

–

30 A

2

–

15 A

Note:This is the minimum required to provide 2.5 KW per PSM. Based on facilities guidelines, you should overprovision the MX2008 router. The two numbers listed in the current columns reflect the distribution of phases from the feed to PSM. For example, from one feed each phase goes to two PSMs and from the other feed each phase goes to only one PSM.

Power supply modules (PSMs)—All nine AC, DC, 240 V China, or universal HVAC/HVDC PSMs in a system share the load. If one PSM fails in a redundant configuration, the remaining eight PSMs provide power to FRUs. Up to nine PSMs might be required to supply power to a fully configured router. Nine PSMs supply power to the two RCBs (active and redundant), eight SFBs, ten MPCs, and two fan trays (active and redundant).

Cooling system—The cooling system has a total of two fan trays—which are controlled and monitored by the host subsystem. The fan trays are at the bottom and are used to cool RCBs, SFBs, and ten line cards. If a fan fails or the temperature rises above the temperature threshold, the speed of the remaining fans is automatically adjusted to keep the temperature within the acceptable range (see MX2008 Cooling System Description).

The MX2008, MX2010, and MX2020 routers support the same power modules (AC/DC or HVAC/HVDC PSMs and PDMs).

See Also

MX2008 Field-Replaceable Units

Field-replaceable units (FRUs) are router components that can be replaced at the customer site (see Table 5). Replacing most FRUs requires minimal router downtime. The router uses the following types of FRUs:

Hot-removable and hot-insertable FRUs—You can remove and replace these components without powering off the router or disrupting the routing functions.

Hot-pluggable FRUs—You can remove and replace these components without powering off the router, but the routing functions of the system are interrupted when the component is removed.

Note:Before you replace most host subsystem components, such as the RCBs, you must take the host subsystem offline.

Table 5 lists the FRUs for the MX2008 router.

Hot-Removable and Hot-Insertable FRUs |

Hot-Pluggable FRUs |

|---|---|

|

|

See Also

MX2008 Router Hardware Components and CLI Terminology

The MX2008 router supports the components listed in Table 6.

Component |

Hardware Model Number |

CLI Name |

Description |

|---|---|---|---|

Chassis |

|||

Chassis |

CHAS-MX2008 |

MX2008 |

|

AC optimized power chassis |

MX2008-PREMIUM2-AC |

||

DC optimized power chassis |

MX2008-PREMIUM2-DC |

||

Craft interface panel |

MX2008-CRAFT |

Front Panel Display |

|

Cooling System, Including Air Baffle, Fan Trays, and Air Filters |

|||

Fan tray |

MX2000-FANTRAY |

172 mm FanTray - 6 Fans |

|

Optimized power fan tray |

MX2K-FANTRAY |

Optimized Power fan tray |

|

Air filter kit |

MX2000-FLTR-KIT-S |

N/A |

|

Power System Components |

|||

PDM blank cover |

MX2000-PDM-BLANK |

N/A |

|

Power distribution module (PDM) |

MX2000-PDM-DC |

DC 52V Power Dist Module |

|

MX2K-PDM-DC240V |

MX2K 240V HVDC PDM |

MX2000 DC Power Distribution Module (240 V China) Description |

|

MX2K-PDM-HV |

MX2K UNIVERSAL HV PDM |

MX2008 High-Voltage Universal (HVAC/HVDC) Power Distribution Module Description |

|

MX2000-PDM-AC-DELTA |

AC Delta Power Dist Module |

MX2008 Three-Phase Delta AC Power Distribution Module Description MX2000 Three-Phase Delta AC Power Distribution Module Description |

|

MX2000-PDM-AC-WYE |

AC Y Power Dist Module |

MX2008 Three-Phase Wye AC Power Distribution Module Description MX2000 Three-Phase Wye AC Power Distribution Module Description |

|

MX2K-PDM-AC-1PH |

Single-phase AC PDM |

||

MX2K-PDM-OP-AC |

Single-phase AC PDM (6+1) |

||

MX2K-PDM-OP-DC |

Optimized Power DC PDM (6+1) |

||

PSM blank cover |

MX2000-PSM-BLANK |

N/A |

|

Power supply module (PSM) |

MX2000-PSM-AC |

AC 52V Power Supply Module |

|

MX2000-PSM-DC |

DC 52V Power Supply Module |

||

MX2K-PSM-DC240V |

MX2K 240V HVDC PSM |

||

MX2K-PSM-HV |

MX2K UNIVERSAL HV PSM |

MX2008 High-Voltage Universal (HVAC/HVDC) Power Supply Module Description |

|

MICs and MPCs, Including ADC and Transceiver |

|||

MIC |

|||

MPC blank cover |

MX2000-LC-BLANK |

N/A |

|

MPC |

|||

ADC |

MX2000-LC-ADAPTER |

Adapter Card |

|

Transceiver |

Xcvr |

||

Host Subsystem Components |

|||

SFB |

MX2008-SFB2 |

MX2008 Switch Fabric Board 2 |

MX2008 Enhanced Switch Fabric Board (MX2008 SFB2) Description |

SFB blank cover |

MX2008-RE-SFB-BLANK |

N/A |

|

Routing and Control Board (RCB) |

REMX2008-X8-64G |

Control Board |

|

Routing Engine |

RE-MX2008-X8-64G |

||

See Also

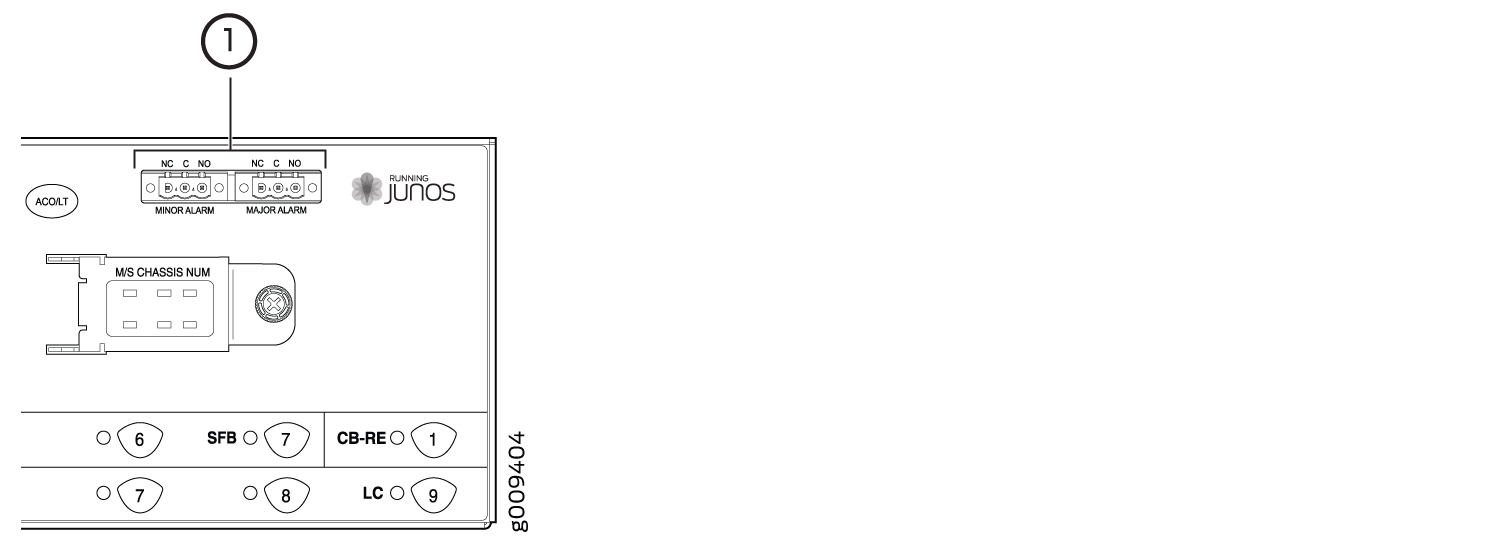

MX2008 Craft Interface Description

The craft interface enables the user to view status and troubleshooting information at a glance and to perform many system control functions. It is hot-insertable and hot-removable.

The craft interface is located on the front of the router and contains LEDs for the router components, the alarm relay contacts, and alarm cutoff button (see Figure 10). Table 7 describes the LEDs, buttons, and connectors.

|

Function No. |

Label |

Description |

|---|---|---|

|

1 |

PSM |

Status LEDs for PSMs 0 through 8 |

|

2 |

FANTRAYS |

Status LEDs for fan trays 0 and 1 |

|

3 |

RE0 (MASTER, ONLINE, and OFFLINE) RE1 (MASTER, ONLINE, and OFFLINE) |

Two sets of status LEDs per host subsystem. There are three LEDs per Routing Engine. |

|

4 |

MINOR ALARM |

Minor Alarm LED for monitoring or maintaining the MX2008 |

|

5 |

MAJOR ALARM |

Major Alarm LED for critical conditions, which can result in system shutdown |

|

6 |

ACO/LT |

Alarm Cutoff/ Lamp Test button. Turns off both minor and major alarms and deactivates the device attached to the corresponding alarm relay contact on the craft interface |

|

7 |

M/S CHASSIS NUM |

Chassis ID Dial and Standalone Dial. One dial is used to indicate the chassis number for multichassis configurations. The second dial is used to indicate whether the chassis is operating in standalone mode or as part of a multichassis system. |

|

8 |

MINOR ALARM–[NC C NO] MAJOR ALARM–[NC C NO] |

Two sets of alarm terminal contacts, each consisting of normal open and normal closed relays that signal a minor or major alarm when broken. |

|

9 |

CB-RE 0 and CB-RE 1 |

Status LEDs for the two RCBs. |

|

10 |

LC 0 through LC 9 |

Status LEDs for the ten line cards. |

|

11 |

SFB 0 through SFB 7 |

Status LEDs for eight SFBs. |

See Also

MX2008 Alarm Relay Contacts on the Craft Interface

The craft interface has two alarm relay contacts for connecting the router to external alarm devices (see Figure 11). Whenever a system condition triggers either the red or yellow alarm on the craft interface, the alarm relay contacts are also activated. The alarm relay contacts are located on the upper right of the craft interface (see Table 8).

Function No. |

Label |

Description |

|---|---|---|

1 |

MINOR ALARM–[NC C NO] MAJOR ALARM–[NC C NO] |

The alarm relays consist of three terminal contacts with normal closed (NC), common (C), and normal open (NO) relays that signal a minor or major alarm when broken. |

See Also

MX2008 Alarm LEDs and Alarm Cutoff/Lamp Test Button

Two large alarm LEDs are located at the upper right of the craft interface. When lit, the circular red LED indicates a critical condition that can result in a system shutdown. A lit triangular yellow LED indicates a less severe condition that requires monitoring or maintenance. Both LEDs can be lit simultaneously.

A condition that causes an LED to light also activates the corresponding alarm relay contact on the craft interface.

To deactivate red and yellow alarms, press the button labeled ACO/LT (for “alarm cutoff/lamp test”), which is located to the right of the alarm LEDs. Deactivating an alarm turns off both LEDs and deactivates the device attached to the corresponding alarm relay contact on the craft interface.

Table 9 describes the alarm LEDs and alarm cutoff button in more detail.

Shape |

Color |

State |

LED Control Name |

Description |

|---|---|---|---|---|

|

Red |

On steadily |

Critical alarm |

Indicates a critical condition that can cause the router to stop functioning. Possible causes include component removal, failure, or overheating. |

|

Yellow |

On steadily |

Warning alarm |

Indicates a serious but nonfatal error condition, such as a maintenance alert or a significant increase in component temperature. |

|

– |

– |

Alarm cutoff/lamp test button |

Deactivates red and yellow alarms. Causes all LEDs on the craft interface to light (for testing) when pressed and held. |

See Also

MX2008 Component LEDs on the Craft Interface

- MX2008 Host Subsystem LEDs and Buttons on the Craft Interface

- MX2008 Power Supply Module LEDs on the Craft Interface

- MX2008 Line-Card LEDs and Buttons on the Craft Interface

- MX2008 SFB LED and Buttons on the Craft Interface

- MX2008 Fan Tray LEDs on the Craft Interface

MX2008 Host Subsystem LEDs and Buttons on the Craft Interface

Each host subsystem has three LEDs, located in the upper middle of the craft interface, that indicate its status. The LEDs labeled RE0 show the status of the Routing Engine on the RCB in slot 0. The LEDs labeled RE1 show the status of the Routing Engine on the RCB in slot 1. Table 10 describes the functions of the host subsystem LEDs.

Label |

Color |

State |

Description |

|---|---|---|---|

MASTER |

Green |

On steadily |

Host is functioning as the primary. |

ONLINE |

Green |

On steadily |

Host is online and is functioning normally. |

OK/FAIL |

Red |

On steadily |

Host is installed but the Routing Engine on the RCB is offline. |

– |

Off |

Host is not installed. |

If you need to take the Control Board offline, you must first take the Routing Engine offline. The Routing Engine gets powered by the Control Board. The RCB is an integrated board and a single FRU that provides Routing Engine and Control Board functionality.

MX2008 Power Supply Module LEDs on the Craft Interface

Each power supply module (PSM) has one bicolor LED on the craft interface that indicates its status. The LEDs, labeled 0 through 8, are located on the upper left of the craft interface next to the PSM label. Table 11 describes the functions of the PSM LEDs on the craft interface.

Label |

Color |

State |

Description |

|---|---|---|---|

PSM |

Green |

On steadily |

PSM is functioning normally. |

Red |

On steadily |

PSM module has failed or power input has failed. |

MX2008 Line-Card LEDs and Buttons on the Craft Interface

Each line card (or MPC) has one bicolor LED on the craft interface that indicates its status. The LEDs, labeled LC 0 through LC 9, are located along the bottom of the craft interface. Table 12 describes the functions of the LEDs present on the MPC.

Label |

Color |

State |

Description |

|---|---|---|---|

LC |

Green |

On steadily |

Line card functioning normally. |

Blinking |

Line card is transitioning online or offline. |

||

– |

Off |

The slot is not online. |

|

Red |

On steadily |

Line card has failed. |

There are ten push buttons located next to each of the line card LEDs on the craft interface. These buttons are used to place the line cards online or offline. When a line card is inserted into an adapter card, and installed into the MX2008 router, the online/offline buttons can turn both the line card and its adapter card on or off.

When installing an adapter card without the line card, the online/offline buttons have no effect.

MX2008 SFB LED and Buttons on the Craft Interface

Each SFB has one bicolor LED on the craft interface that indicates its status. The SFB LEDs, labeled 0 through 7, are located along the bottom of the craft interface. Table 13 describes the functions of the SFB LED.

Label |

Color |

State |

Description |

|---|---|---|---|

SFB |

Green |

On steadily |

SFB functioning normally. |

Blinking |

SFB is transitioning online or offline. |

||

– |

Off |

The slot is not online. |

|

Red |

On steadily |

SFB has failed. |

There are eight push buttons located next to each of the SFB LEDs on the craft interface. These buttons are used to place the SFBs online or offline.

MX2008 Fan Tray LEDs on the Craft Interface

The fan tray LEDs, labeled 0 and 1, are located on the top middle of the craft interface. Table 14 describes the functions of the fan tray LEDs.

Label |

Color |

State |

Description |

|---|---|---|---|

FANTRAYS |

Green |

On steadily |

Fan is functioning normally. |

Red |

On steadily |

Fan in a fan tray has failed. Fan tray has failed. |

See Also

MX2008 Cable Manager Description

The MX2008 router supports the following cable managers:

The MX2008, MX2010, and MX2020 routers support the same cable managers.

Standard Cable Manager

The standard cable manager consists of the following components:

-

Card-cage cable manager—MX2000-CBL-MID

-

Lower cable manager—MX2000-CBL-BTM-S

-

DC power cable manager—MX2000-DC-CBL-MGR-S

-

Cable manager for the DC PDM (240 V China) and the universal (HVAC/HVDC PDM)—MX2K-HV-CBL-MGR

The lower cable manager (see Figure 12) is located just below the lower card cage, has a removable cover that is secured by two captive screws with access to rows used for routing and securing the cables away from the front of the Modular Port Concentrators (MPCs) and Modular Interface Cards (MICs) (see Figure 13).

You can use cable strips or other ties to gently secure the cables in the lower cable manager. To secure the cables in place, loop the tie through the cable anchor and secure the tie.

Each DC PDM has one cable manager. The DC cable manager routes cables away from the rear of the PDMs (see Figure 12).

You can use cable strips or other ties to gently secure the cables in the DC cable manager. To secure the cables in place, loop the tie through the cable anchor and secure the tie. You can pull the DC cable manager up and outward to lock it into the maintenance position.

The card-cage cable manager (see Figure 14) is located in the upper card cage, which has rows for routing and securing the cables away from the front of the RCBs and SFBs.

You can use cable strips or other ties to gently secure the cables in the card-cage cable manager. To secure the cables in place, loop the tie through the cable anchor and secure the tie. To access the air filter, the cable manager needs to be opened.

Extended Cable Manager

The extended cable manager consists of the following components:

-

Extended lower cable manager—MX2000-CBL-BTM-XT-S

-

Extended DC cable manager—MX2020-DC-CBL-MGR-XT-S

The extended cable manager provides additional support to route and secure a large number of cables away from the front of the MPCs and MICs (see Figure 17).

The extended DC cable manager provides additional support to route and secure a large number of cables away from the rear of the PDMs.

You can use cable strips or other ties to gently secure the cables in the upper and lower extended cable managers. To secure the cables in place, loop the tie through the cable anchor and secure the tie.

See Also

MX2008 Rack-Mounting Hardware

The rack-mounting hardware for the MX2008 router includes:

One large adjustable mounting shelf for mounting in four-post racks or cabinets

Built-in front-mounting flanges on the front of the chassis for front-mounting in a four-post rack or cabinet

One open-frame mounting shelf for mounting in an open-frame rack (optional)

Two center-mounting brackets for mounting the router in an open-frame rack (optional)

Mounting screws

Cage-nuts

There must be a minimum or 24 U of usable rack space when installing the MX2008 router into a rack.